Plastic Lumber

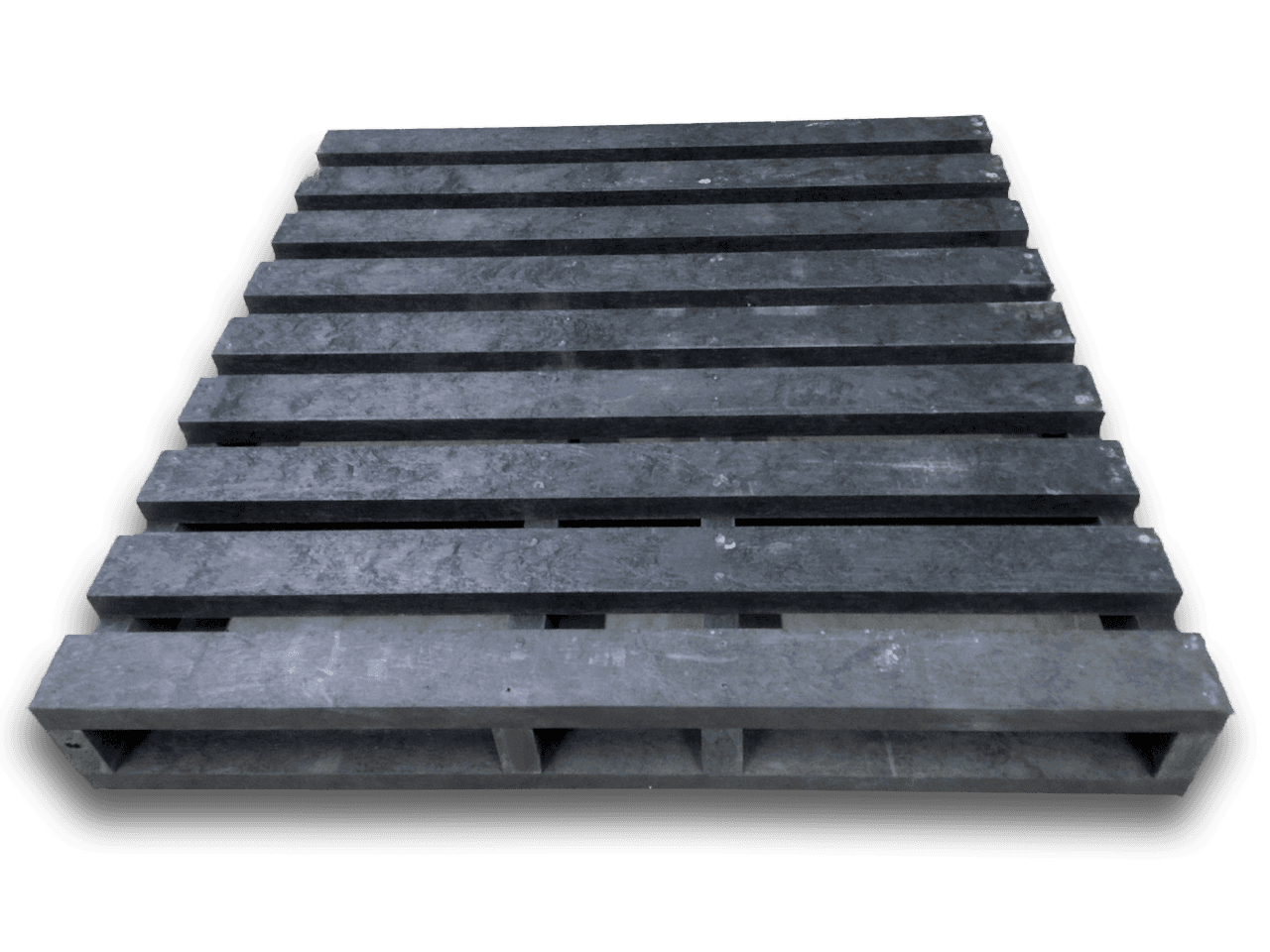

Anything outside, made from wood, can be done from recycled Plastic Lumber and it will last generations

Decks, Fences, Docks, Furniture, Mailbox Posts, Signs, House trim, Address plaques and much more

Everything wood, could be done with plastic

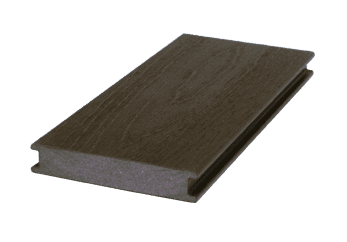

Wood can be beautiful. Who can deny Cherry, Walnut, Maple and Oak have been the building blocks of our country? However, while wood is great indoors, it is in a constant state of decomposition when outdoors. Rotting, cracking, splitting, insects, etc are all part of wood decay. We propose that if it is to be outside, make it from plastic. You really cant tell the difference, except that it looks great every day and doesn't seem to age. Darker colors can show fading over the years, but it is very slight and doesn't seem to show the sun's effects.

What's the difference?

Early on, wood composites made their mark. Go to the big box stores and you will see one color of deck board, and maybe a similar railing system. They are made from 60% wood sawdust and the rest is plastic. They have their issues and if you do your google search you can find the dirt. When you make a product from all plastic you eliminate the problems associated with wood.

Now, as far as plastic is concerned, there are 7 kinds. Turn over a bottle and look for the recycle triangle. In the center is a number. They range from 1 to 7 with PET being the softest and used for water bottles, while 7 would be a hard polycarbonate. High Density PolyEthylene or HDPE is #2 and on the soft end of the scale, however when extruded into a board, you gain quite a bit of strength. We enhance this a couple of ways to make it even stronger. The first is to add fiberglass flakes. It adds about 20% more strength and makes it a structural- load bearing member. The second is to add fiberglass rods down the corners of the boards in the larger sizes and you end up with a board that can be used to build a bridge.